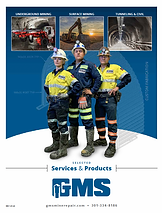

We are GMS and we've been serving the Mining Industry for nearly 40 Years. Our deep experience and broad range of specialized services and products allow us to serve the customer with unmatched efficiency and scale as we continue to grow and adapt to constantly changing markets. We offer Underground and Surface Mining contract labor and services supported by our own custom engineering and fabrication facilities.

More than providing trained professionals and quality products, we are first a Solutions Provider. Our experienced engineers work with you to clearly define and strategically solve the most challenging projects. Then our skilled labor force reliably executes those solutions with precision and professionalism. We’re prepared to tackle even the most demanding jobs and you can be confident that it’s done right.

We exceed expectations.

That’s the GMS way of doing business.

RIPSHH

UPDATED 1-31-24